All in a days training for OneCNC UK

As technical director for OneCNC UK multi-axis training is often now part of my day. It can be challenging work but it can also be enjoyable and rewarding especially when you have nice equipment and a good user.

GMT CNC Machining of 253 New Road Portsmouth PO2 7QY, UK is one of these examples they recently purchased OneCNCXR3 Mill Expert with 5 axis and I was booked to assist with training, sort out any technical issues and assist to set the post for their machines.

Here we have a Heidenhain controlled 5 axis YCM FX350A machining center with a X700 Y520 Z 480 travel and 40T tool capacity, which is just one of many CNC machines in this shop.

The first task was to set the post, then establish the machining procedure, the part holding fixture and program the part. We then set the part in the vice and probed the position.

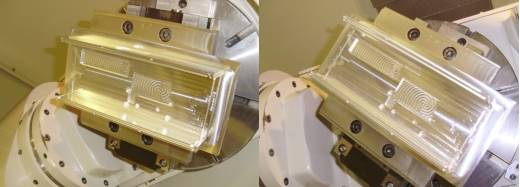

The next 2 pictures I took during the machining process.

The next pictures show another picture in the process of machining and finally 2 pictures of the finished part.

If you have need of improving your CNC efficiency and you are in the UK call the OneCNC UK office and we will be only too pleased to do the same for you 2,3,4 or 5 axis.

Peter Gillespie

OneCNC UK

James House

Newport Road, Albrighton

WV7 3HA

United Kingdom

ph. +44 (0)1902373054

OneCNC Updates

OneCNC XR9 Release 74.93

Jul 25 2024

OneCNC XR9 Release 74.90

Jul 11 2024

OneCNC XR9 Release 74.86

May 02 2024