OneCNC Installs 5,000th HS Machining Customer

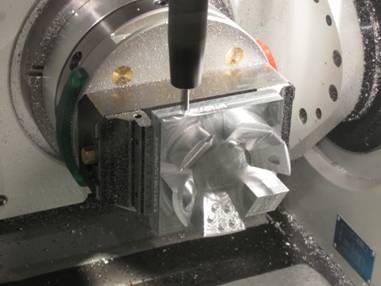

OneCNC installed the 5,000th new HS machining OneCNCXR3 customer Friday 4th September. Quite an achievement having 5,000 users of our latest high technology product. This has only happened because of the enormous acceptance of this eighth generation Windows CAD-CAM product by our many customers.

With 5,000 8th generation Windows systems now installed using the revolutionary new High Speed machining and High Speed Rest machining proves how well OneCNC is being accepted by our customers.

OneCNC now has more than 17,000 installed seats of software in manufacturing covering a wide spectrum of industries.

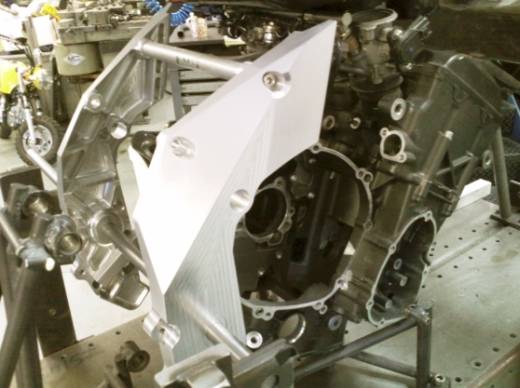

Chris Florey from CDF Racing is seen here in front of his new Haas Mini Mill having just had the system installed and going through the familiarization training with Renny from OneCNC UK.

CDF Racing situated in Kent UK is expanding their manufacturing capabilities and now having purchased OneCNC is looking forward to producing many new quality parts.

We wish Chris and CDF Racing our very best wishes for their future success in manufacturing performance parts.

CDF Racing Ltd

Unit 27

Space Business Centre & Knights Road

Rochester

Kent

me2 2bf

UK

OneCNC Updates

OneCNC XR9 Release 74.93

Jul 25 2024

OneCNC XR9 Release 74.90

Jul 11 2024

OneCNC XR9 Release 74.86

May 02 2024